In 2016, I built a prosthetic aquatic device for below-knee amputees

Let me tell you a short story

When I was the Navy in 2008, I wanted to be an air rescue swimmer, jumping out of helicopters to save soldiers in choppy waters. Unfortunately, I didn’t make the program, instead I spent five years of service as a crane operator, event planner, and weapons specialist. When I left the military, I studied product design at Northeastern University. My capstone project turned into much more than was expected. Since leaving the military, I have been helping out for veteran non-profits, including the Veterans of Foreign Wars, Salute to Military Golf Association and Operation Blue Pride.

In 2017, I found another way to help my veteran community, and that was through swimming and scuba diving. It all started in 2016, when I joined Operation Blue Pride, a non-profit organization geared to help veterans cope with anxiety and PTSD through scuba diving. I went through the program myself and then volunteered. While volunteering during one of the seasonal programs, I had a veteran who had bilateral below-the-knee amputations. Despite all odds, he wanted to learn how to scuba dive. If you know anything about diving, you rely almost 90% on your legs and feet to guide and propel you through the water. This was a problem for this veteran and I took it upon myself to dive into this new opportunity.

The opportunity

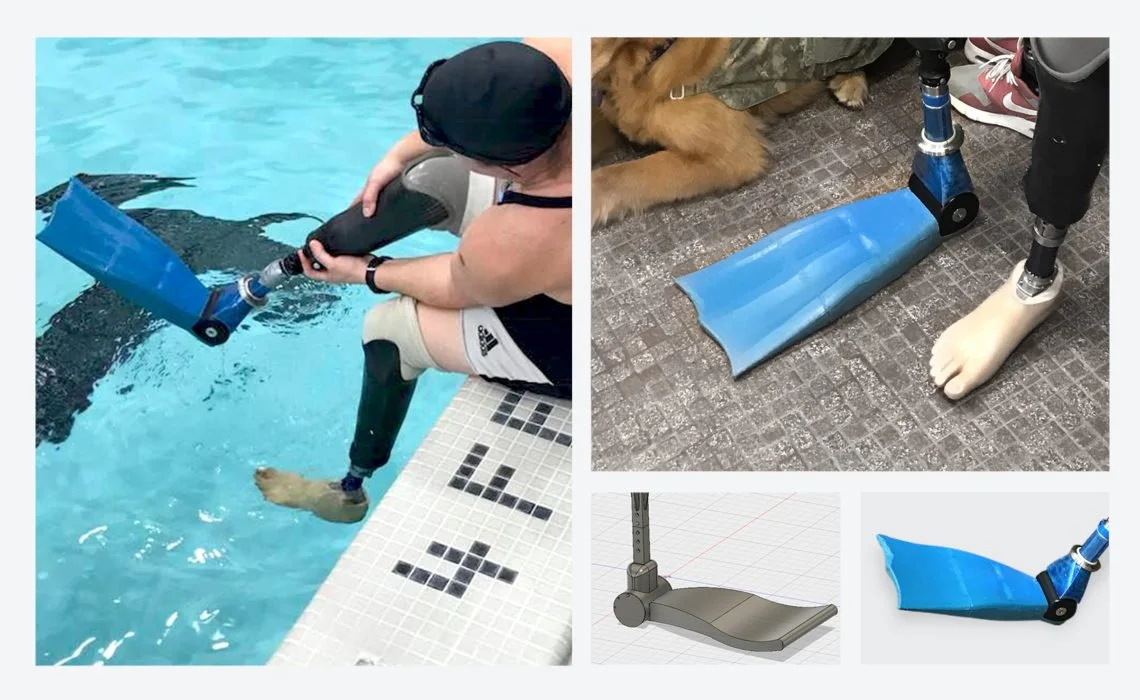

Prosthetics designed specifically for water sports started appearing in the last decade, driven by veteran rehabilitation organizations like Soldiers Undertaking Disabled Scuba (SUDS) and California Polytechnic State University’s QL+ Laboratory. It’s a unique engineering challenge: Most underwater leg prosthetics only function as fins or flippers, but not pegs, so amputees can’t walk into the water. The goal of the project was to develop a prosthetic that an individual can put on at the beach or by the pool and walk into the water. Once in the water, rotate the device for swimming mode.

I spent the majority of my education learning about user experience and user interface design, not industrial or product design, so this was a major and unforgettable learning experience. I followed the same process that I would if it were a digital product. I started with user interviews with veterans and prosthetists and then learned about 3D printing and materials and then learned about ergonomics and fluid dynamics. Eventually, I started building using whatever material I could get my hands on. Soon, after several iterations, I built my first functional prosthetic out of 3D printed plastic, resin and titanium parts.

The birth of the Triton Flipper

I called my prototype the Triton Fipper, the first prosthetic to double as both leg and flipper. The dual functionality is made possible by an attachment system that I developed while studying design at Northeastern University. In 2016, my professor asked me to submit the Triton Flipper into Northeastern’s Research Innovation Scholarship Expo (RISE). Once RISE came around later on in the year, I was all set to go, I had a working Triton Fipper, a model for the device (Army Veteran friend) and a coupe of boards displaying my product. RISE was insane and amazing! There were over 1000 students all trying to showcase their new innovations, products and science research. But I knew I had something big, a breakthrough into the prosthetic industry, building an affordable adaptive device for amputees. I ended up winning RISE’s Undergraduate Interdisciplinary Topics award. That day changed everything for me and the Triton Flipper!

Expansion of the Triton Flipper

Since winning the RISE award, I had a slew of people who were interested in getting the Triton Flipper developed. In late 2016, I won 3 grants. One was from Shapeways, for $1,000 for 3D printing, the other from Northeastern University’s Generate for $5,000 and a team of engineers to help build a new device. The final grant was for $20,000 from Northeastern University’s Origin organization to help early stage startups . This decide was built in a matter of 6 months with 5 engineers. We ended up testing the device in the Northeastern University pool with Christy Gardner, an Army Veteran from Maine, and team USA hockey player. The day in the pool was the best day of the entire project. We were able to get Christy in the water and swim laps with the device. Yes, there were a lot of things to tweak and adjust for a future design, but it was super impactful and a great learning experience.

In October of 2016, I was approached by a startup advisor and investor to join 2017’s Boston Pitch Competition at the Boston Public Library. The winner of this pitch competition won $20,000. Although I didn’t place in the competition, I was approached by several investors after the competition to continue funding my project.

In December of 2017, I created my very own team of engineers to continue building a new prototype, one that was made with carbon fiber and titanium. In July of 2018, the project was discontinued due to a new job in Colorado.

Articles about this project:

“I read about your article on Shapeways Magazine. The flipper you designed sounds like the perfect type of device for my son.”